Tool makers are able to optimally design mold tempering, runner systems, hot or cold runners and ejector packages in the first attempt.

This frontloading shortens development times and minimizes risks. SIGMASOFT® Virtual Molding supports solutions for complex questions in injection molding ranging from the first design to production:ĭevelopers and designers distinguish possible production problems or critical behavior in the parts long before a real prototype exists.

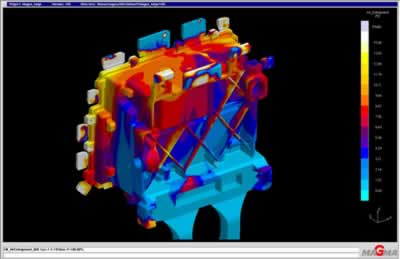

SIGMASOFT® Virtual Molding is development in cooperation with MAGMA in Aachen, who set the standard for 3D metal casting process simulation with MAGMASOFT® at the end of the 1980ies and is today’s worldwide technology and market leader. Since 1998 SIGMA in Aachen, Germany, is the pioneer and pacemaker of this technology. Thus SIGMASOFT® Virtual Molding delivers sound information as only acceptable basis for accurate and reliable decisions. The key of the SIGMASOFT® Virtual Molding principle is the real 3D simulation of flow, heat flux and warpage for injection molding including the complete mold with all details. The difference is SIGMASOFT® Virtual Molding’s unique, holistic approach for the simulation of injection molding processes. This includes trouble-shooting for unforeseen challenges, but also revealing of hidden potential.

The SIGMASOFT® Virtual Molding technology was developed to overcome today’s big challenges for development, mold design and production in injection molding.

0 kommentar(er)

0 kommentar(er)